Jetty Or Terminal Constructions And Maintenance

Leos Maritime provides precision engineered jetty and terminal construction services designed for strength, safety and longevity. From design to completion, our projects meet global standards, withstand harsh marine conditions and ensure seamless port and terminal operations.

Geotextile Laying

Leos Maritime specializes in the meticulous laying of geotextiles, an essential process in reinforcing and stabilizing various soil structures. Geotextiles are crucial for erosion control, drainage management and soil stabilization, offering effective solutions in diverse construction and environmental projects.

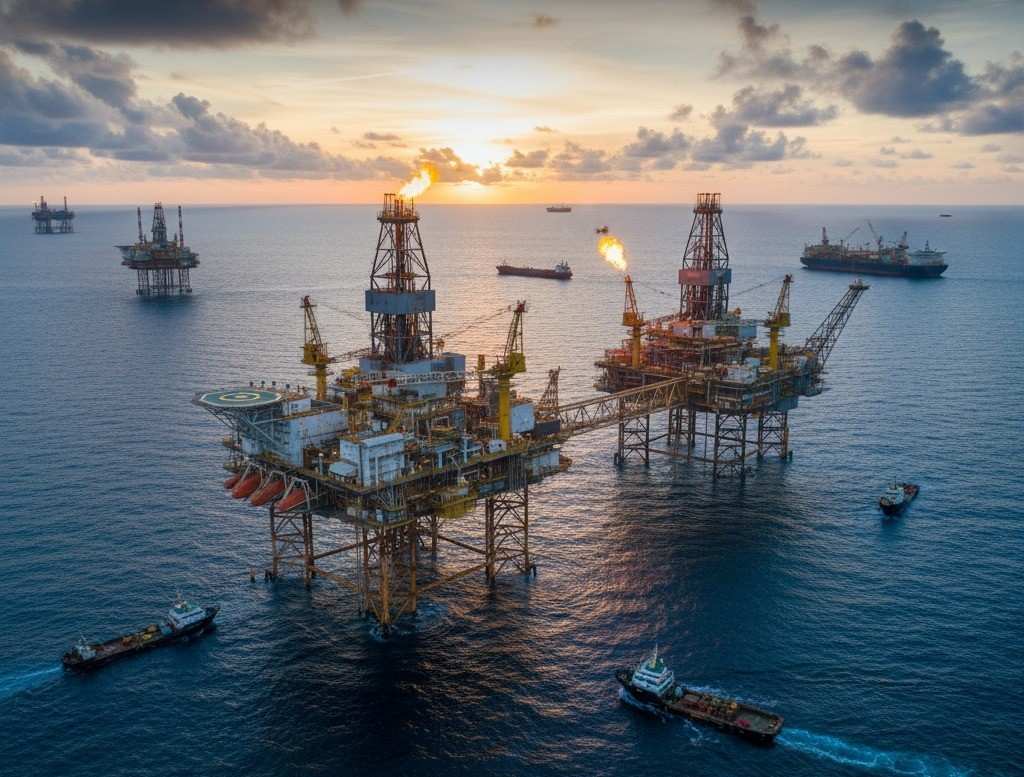

Offshore Infrastructure And Support

Leos Maritime delivers specialized offshore infrastructure and support solutions designed for the oil & gas, renewable energy and maritime sectors. Our services cover the full lifecycle—from project planning and construction to deployment, inspection and long-term operational support. By combining engineering expertise with advanced marine technology, we provide safe, efficient and cost-effective solutions.

Oil Rig Maintenance And Repair

Oil rigs, whether onshore or offshore, are vital structures that enable the drilling and extraction of oil and natural gas. Offshore platforms, in particular, are engineered to operate in challenging environments such as deep waters and harsh weather conditions. These rigs are highly complex and require constant monitoring, planned servicing and specialized repair to remain operational and safe.

Windmill Or Offshore Wind Farm Installation

Offshore wind farms are the backbone of sustainable energy. Our installation services combine precision, safety, and efficiency to deliver world-class results. We ensure that every project is delivered on schedule, within budget, and to the highest safety standards.

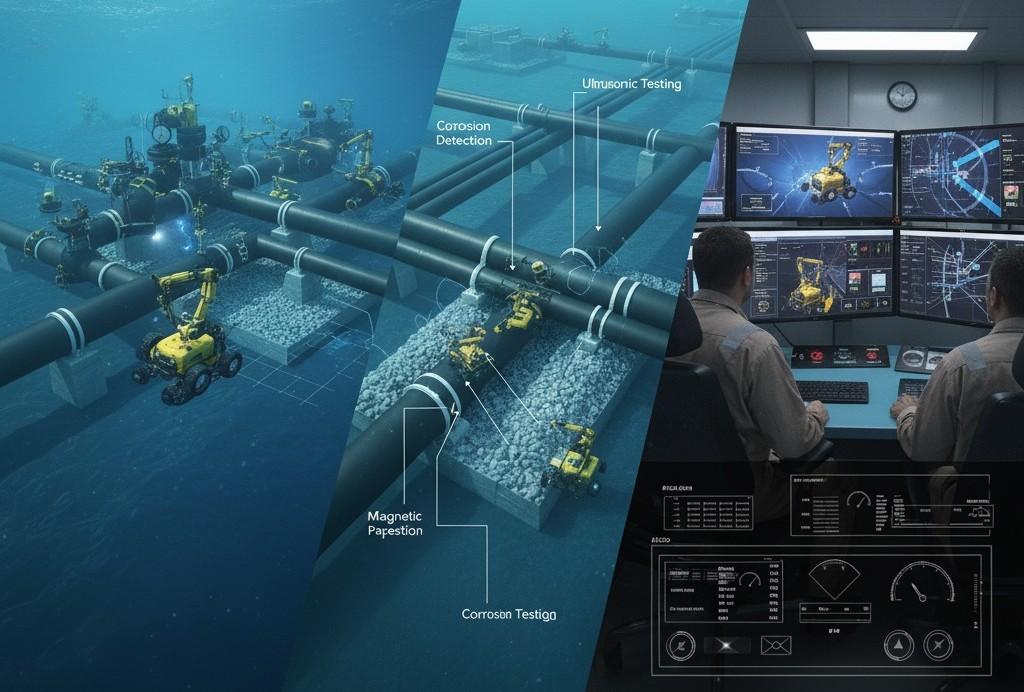

Subsea Pipeline Installation And Maintenance

Leos Maritime provides complete subsea pipeline installation and maintenance services for offshore energy projects. From initial engineering and route planning to installation, inspection and long term maintenance, we ensure reliable, safe and cost effective operations. Our expertise covers shallow water, deepwater and challenging environments while adhering to international safety and environmental standards.

PLEM Inspection With ROV

Pipeline End Manifolds (PLEMs) are critical subsea structures in offshore oil and gas production systems. They function as control and distribution hubs, routing hydrocarbons from pipelines to FPSOs, refineries, floating storage units and shore facilities. Ensuring the integrity of these subsea manifolds is essential for uninterrupted operations, regulatory compliance and asset protection.

Pile Cutting And Removal

Underwater pile cutting is the process of cutting through metal structures of a Pipe that require repairs or modifications. This process is commonly used for removing damaged sections of the pile or other metal components of the piles. There are two main types of underwater ship cutting wet cutting and dry cutting.

Diamond Saw Cutting

During the maintenance and repair of seabed oil pipelines, cutting is required when breakages occur. Traditional underwater cutting methods are difficult and inefficient for such complex operations. Diamond wire saw technology provides an effective solution for subsea cutting challenges.